Search This Supplers Products:precision machinery partsmachining partsauto partsspare parts

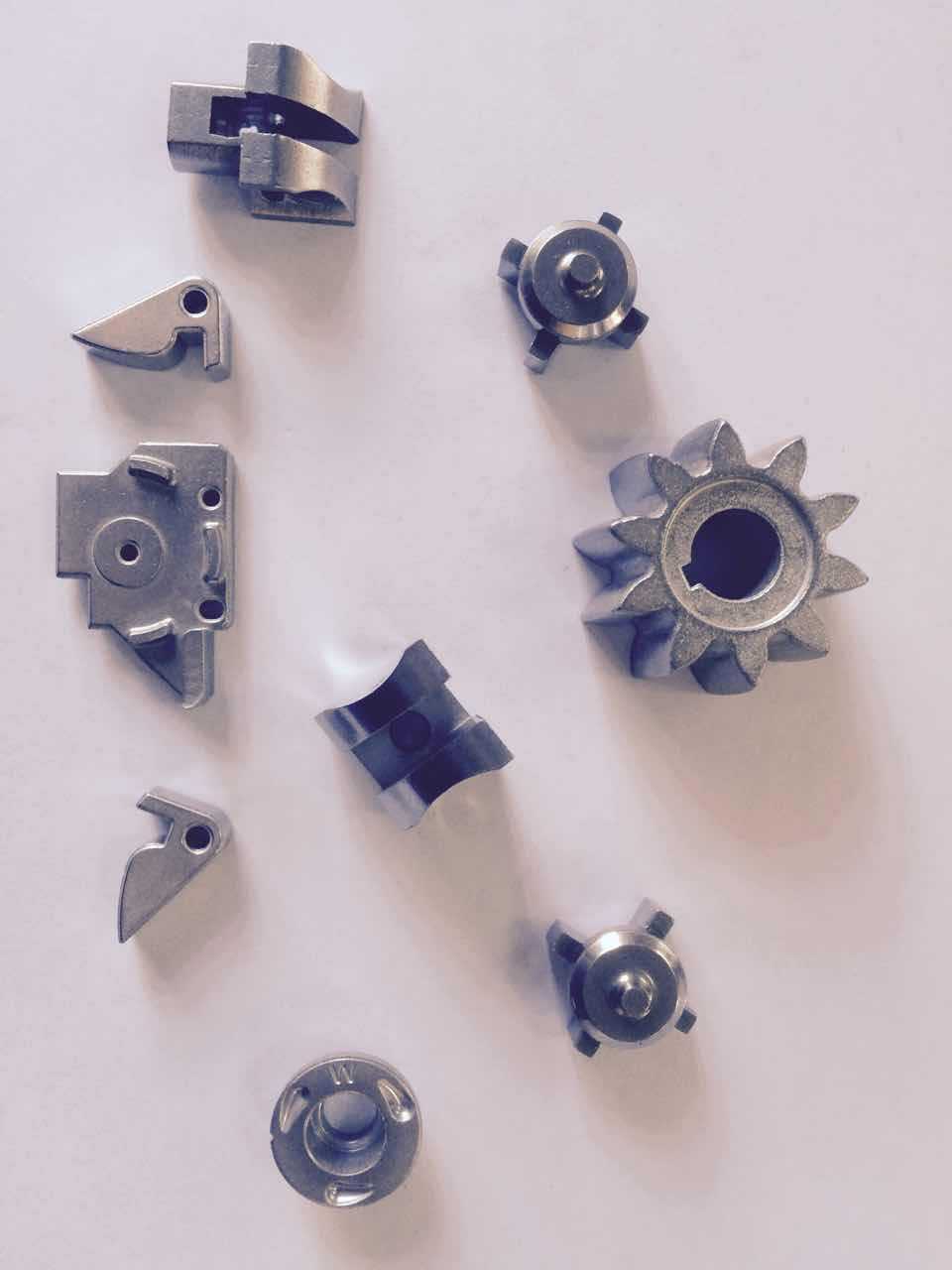

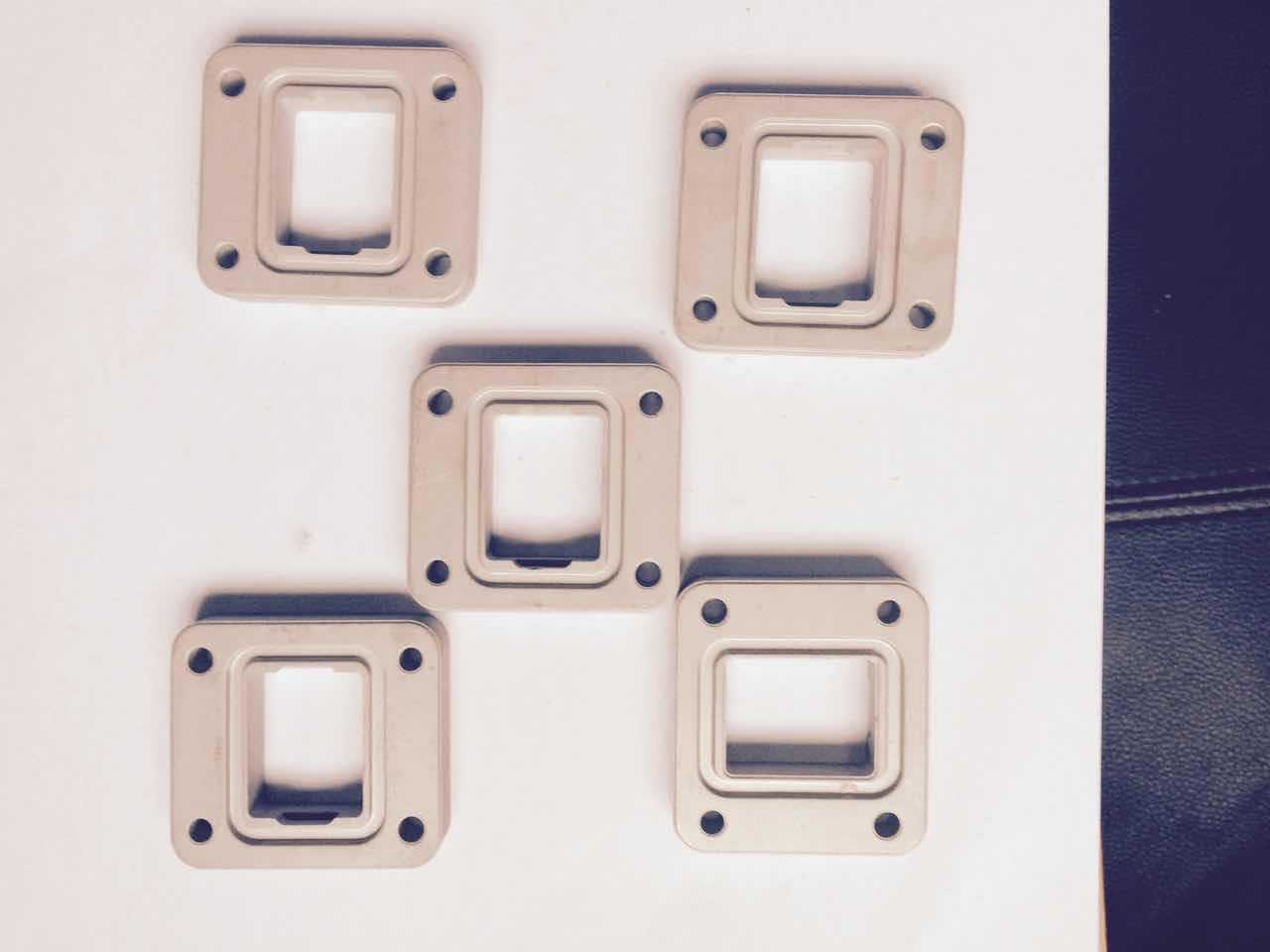

Special-shaped powder metallurgy metal mechanical fittings

- group name

- hardware fitting

- Min Order

- 1 piece

- brand name

- Hicoin

- Nearest port for product export

- Tian Jin, Shang Hai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal

- update time

- Thu, 18 Jan 2018 11:43:30 GMT

Paramtents

Place of Origin Tianjin China (Mainland)

Material Cemented carbide

Type Powder metallurgy parts

Powder pretreated Powder annealing

Powder preparation method Atomization method

Molding method Molding

Material used in manufacturing Stainless Steel、 Aluminium alloy、 Pure copper, Bronze, High strength steel, Pure aluminum, Alloy, etc.

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Powder metallurgy is a process technology for making metal or metal powder

(or mixture of metal powder and non-metal powder) as raw material, forming

and sintering metal materials, composite materials and various types of products.

Powder metallurgy is similar to the production of ceramics, so a series of new

powdermetallurgy technology can also be used in the preparation of ceramic

materials. Because of the advantages of powder metallurgy technology, it has

become the key to solve the problem of new materials, and plays an important

role in the development of new materials.

Powder metallurgy has unique chemical composition and mechanical

and physical properties, and these properties can not be obtained by

traditional method of melting and casting. Powder metallurgy technology

can be directly used to make porous, semi dense or fully dense materials

and products, such as oil bearing, gear, cam, guide rod, cutter and so on.

Our company has advanced mechanical powder forming presses at home,

which is fully equipped with the pressure tonnage is large, medium and small,

and can fully meet the needs of large and small size parts of the customer.

The product involves: auto parts, automobile shock absorber piston, motor

gear, auto pump parts, high strength electric tools, bevel gears, sewing machine

parts, household appliances, office equipment parts, complex parts, precision

oil bearings, stainless steel, copper base parts etc..Years of experience in

producing auto parts, For high-density, high-intensity, high-precision and

complex shape, powder metallurgy products have strong strength in research

and manufacture, and can help customers solve various quality problems in

the production process.